Compressed Air Pipe System

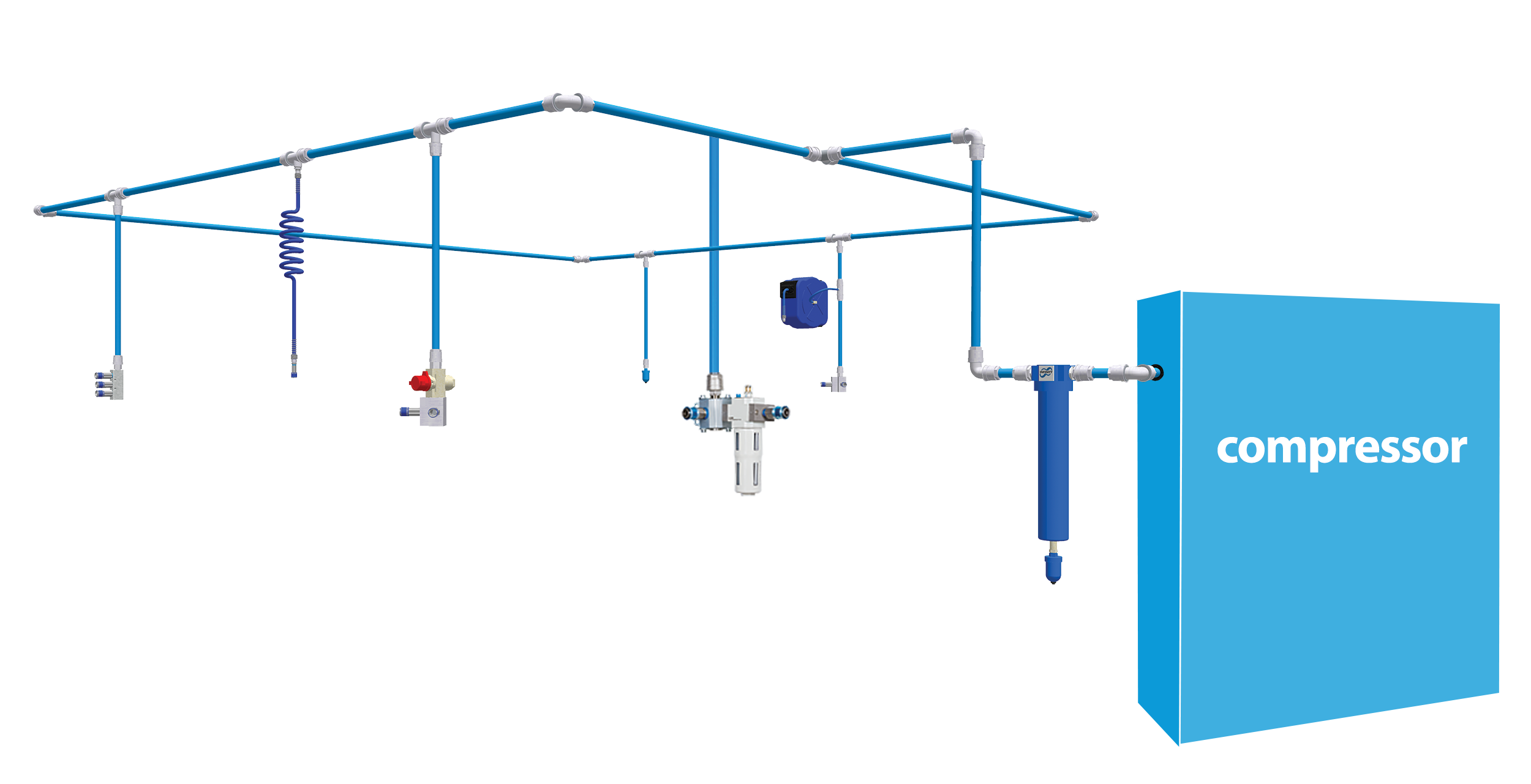

Compressed air pipe system. Contact us to receive more information about different types of compressed air pipes and fittings. Youll get the expertise and guidance you need at every step you can build your perfect compressed air piping system quickly and effortlessly. Founded in 1997 AIRpipe quickly established themselves as a manufacturer of high-quality compressed air pipe systems.

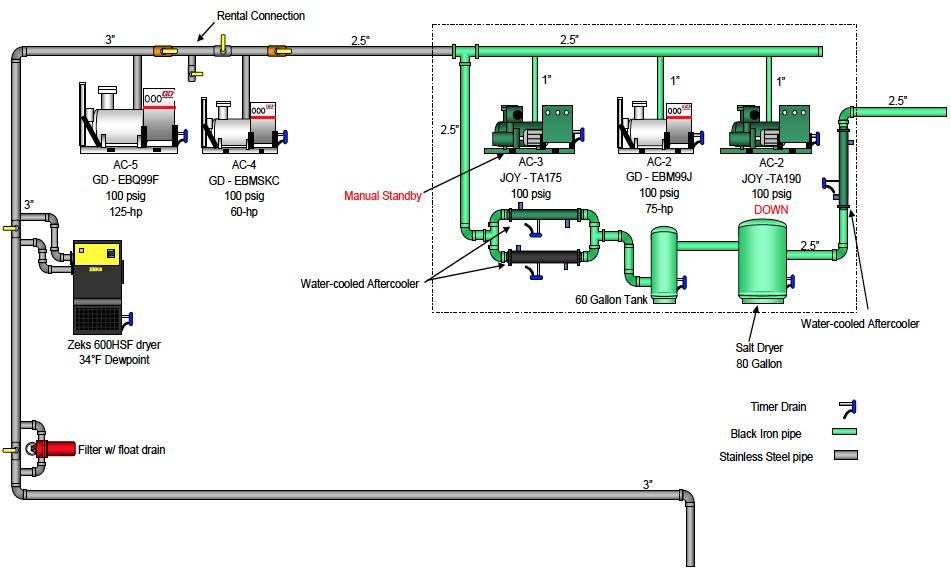

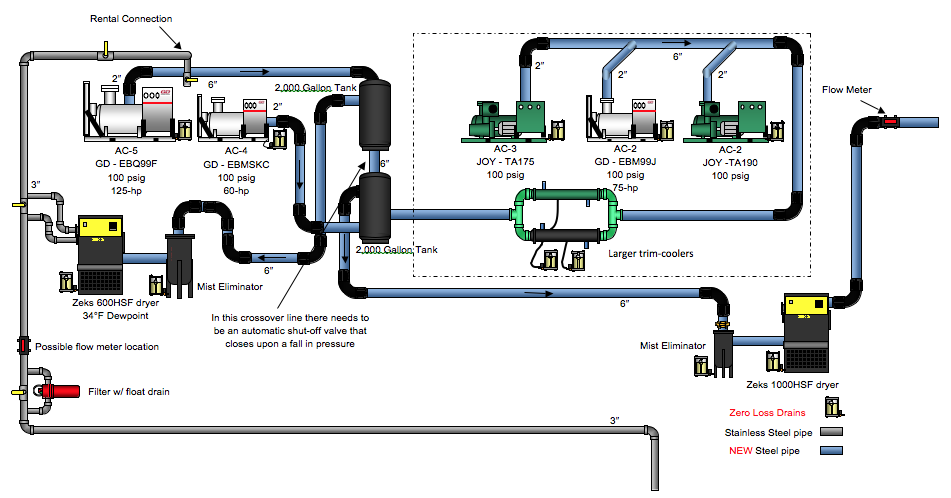

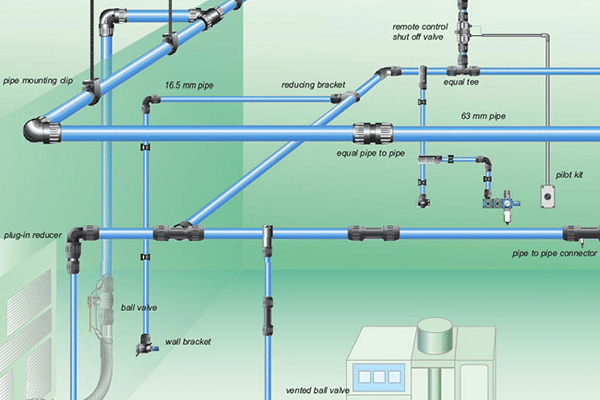

To deliver compressed air to where it is needed. The cost of a com-plete compressed air system and pneumatic tools is relatively small in comparison with the utility provided by their use. Our AIRnet compressed air pipe systems come in a wide range of pipe sizes from ¾ inch to 6 inch.

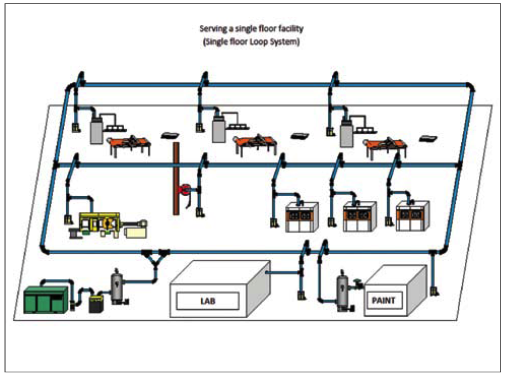

MaxLine is an industrial compressed air piping system that installs in half the time of traditional methods. Piping options made from various types of metal are the more traditional choice for. The purpose of compressed air piping systems is simple.

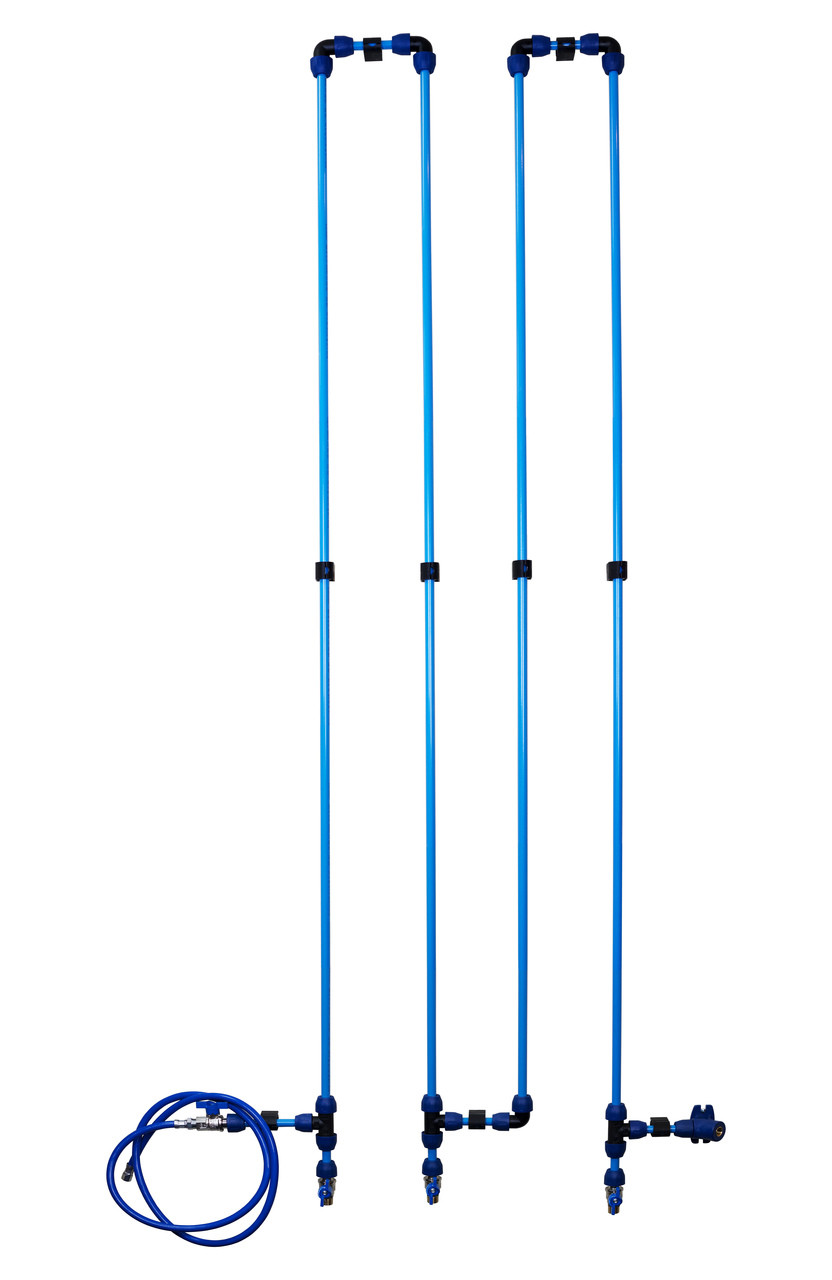

The Secret is in the Pipe. Our invention for adaptability ensures a perfect fit regardless of cable or pipe size. Equipping compressed air pipe systems with brackets that incorporate an upward loop is essential-even when a dryer is used.

Operating in the air compressor and transmission industry the company employs specialist staff who follow the entire production development cycle starting from design and ending with final manufacture. Choose a pipe system preview the layout in 3D and order your parts online with our easy-to-use compressed air line system design tool. Heres an example calculation using the compressed air pipe sizing table table 1 and the equivalent pipe length table table 2.

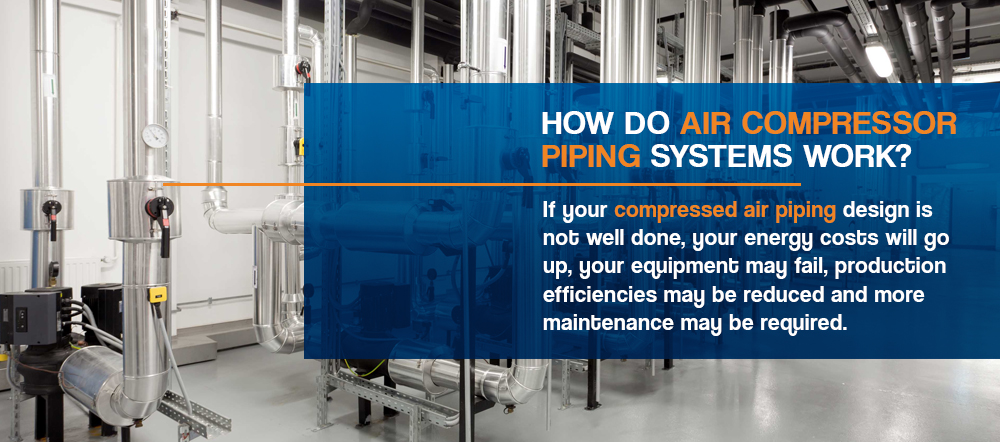

Ad World-leading provider of flexible modular-based seals for cables and pipes. Compressed air flow is really no different than traffic flow on the highway. However designing a compressed air system is more difficult than you might imagine the compressed air has to be delivered with sufficient volume good enough quality and enough pressure to power the components that require compressed air.

Ad World-leading provider of flexible modular-based seals for cables and pipes. Maxair Compressed air pipe and fittings suitable for factory air mains.

Lets say we have a rotary screw compressor of 30 kW that can supply 250 Nm3hour normal cubic meters per hour.

Our invention for adaptability ensures a perfect fit regardless of cable or pipe size. This way any pressure drop that occurs will be kept at a minimum level. Equipping compressed air pipe systems with brackets that incorporate an upward loop is essential-even when a dryer is used. Contact us to receive more information about different types of compressed air pipes and fittings. Heres an example calculation using the compressed air pipe sizing table table 1 and the equivalent pipe length table table 2. What is the Best Piping Material for Compressed Air Systems. Goal of an Efficient Compressed Air System. Two systems are commonly used for distribution piping. Piping options made from various types of metal are the more traditional choice for.

When you need the best most efficient piped for compressed air at the best price choose the FastPipe system. Equipping compressed air pipe systems with brackets that incorporate an upward loop is essential-even when a dryer is used. Our invention for adaptability ensures a perfect fit regardless of cable or pipe size. Lets say we have a rotary screw compressor of 30 kW that can supply 250 Nm3hour normal cubic meters per hour. It is a semi flexible tubing that comes in a 100 ft or 300 ft coil and uses compression fittings for leak proof performance. Compressed air flow is really no different than traffic flow on the highway. Heres an example calculation using the compressed air pipe sizing table table 1 and the equivalent pipe length table table 2.

Post a Comment for "Compressed Air Pipe System"